The solutions developed and manufactured by the Teadit Group guarantee the excellence in the sealing of aggressive chemical fluids in the most diverse industrial applications.

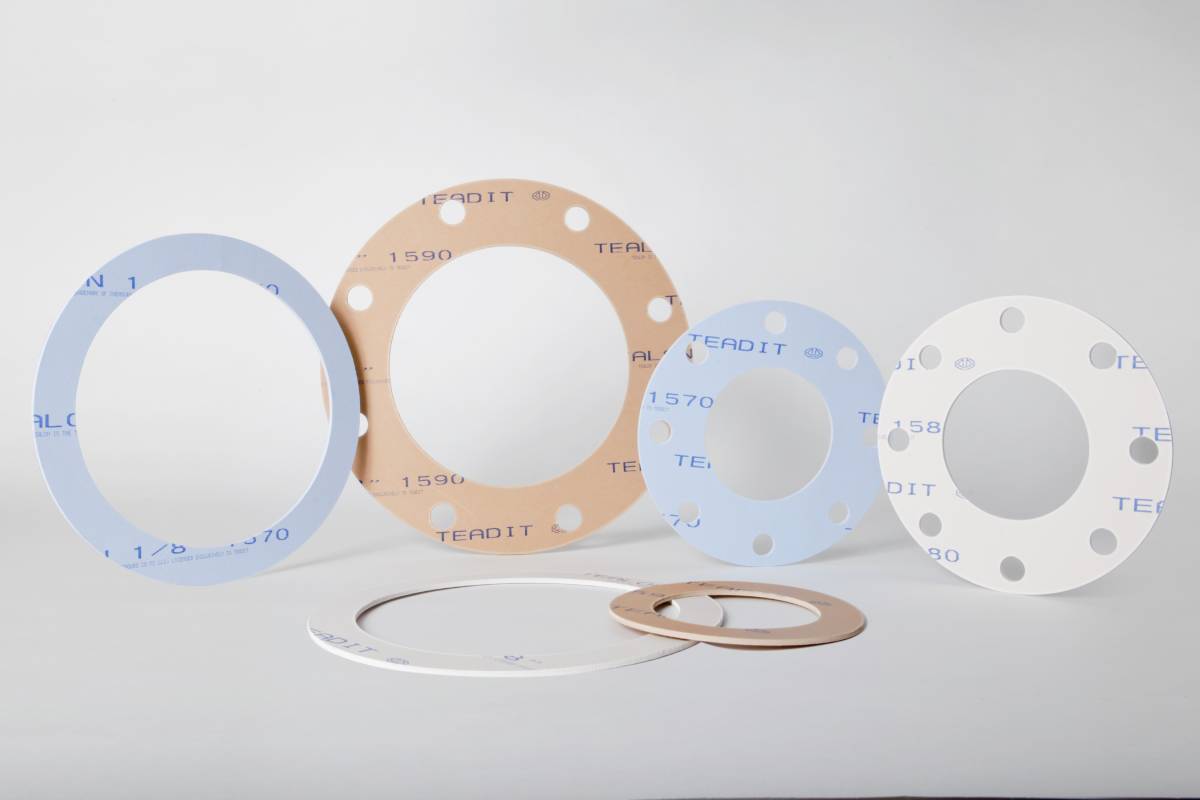

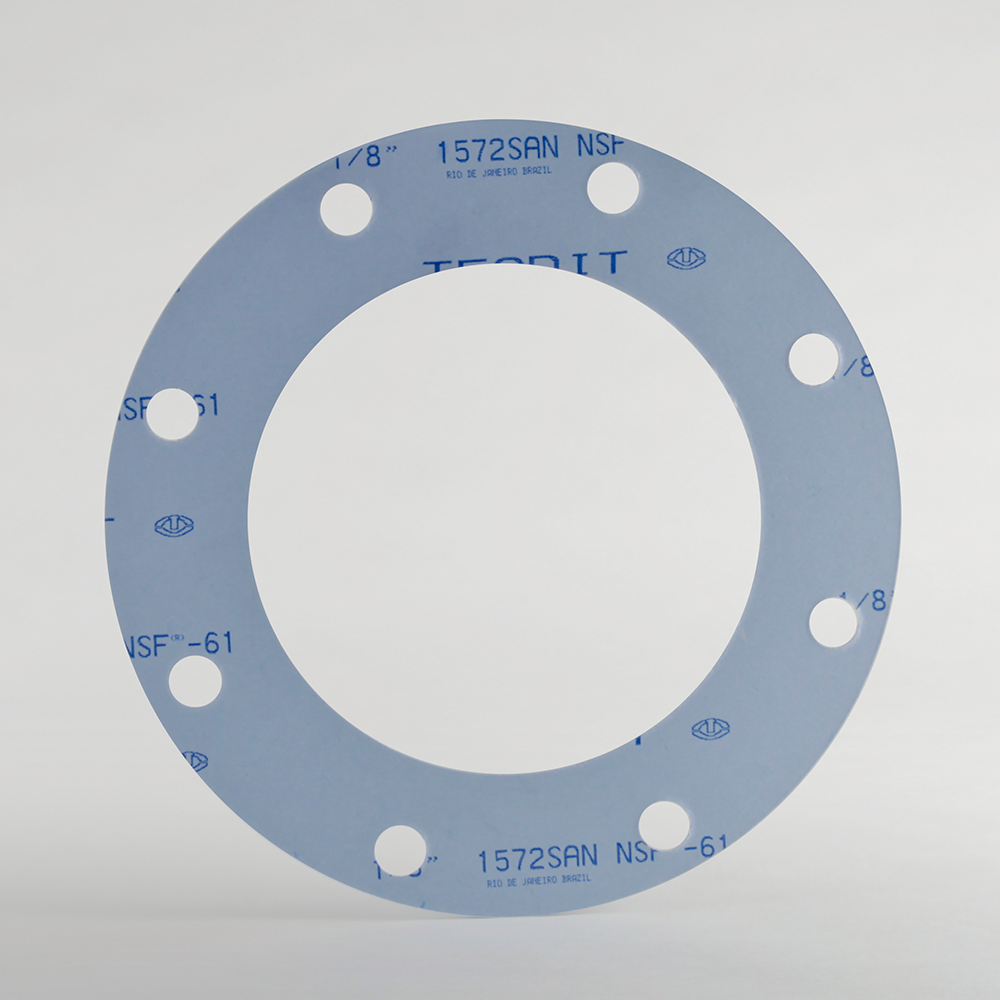

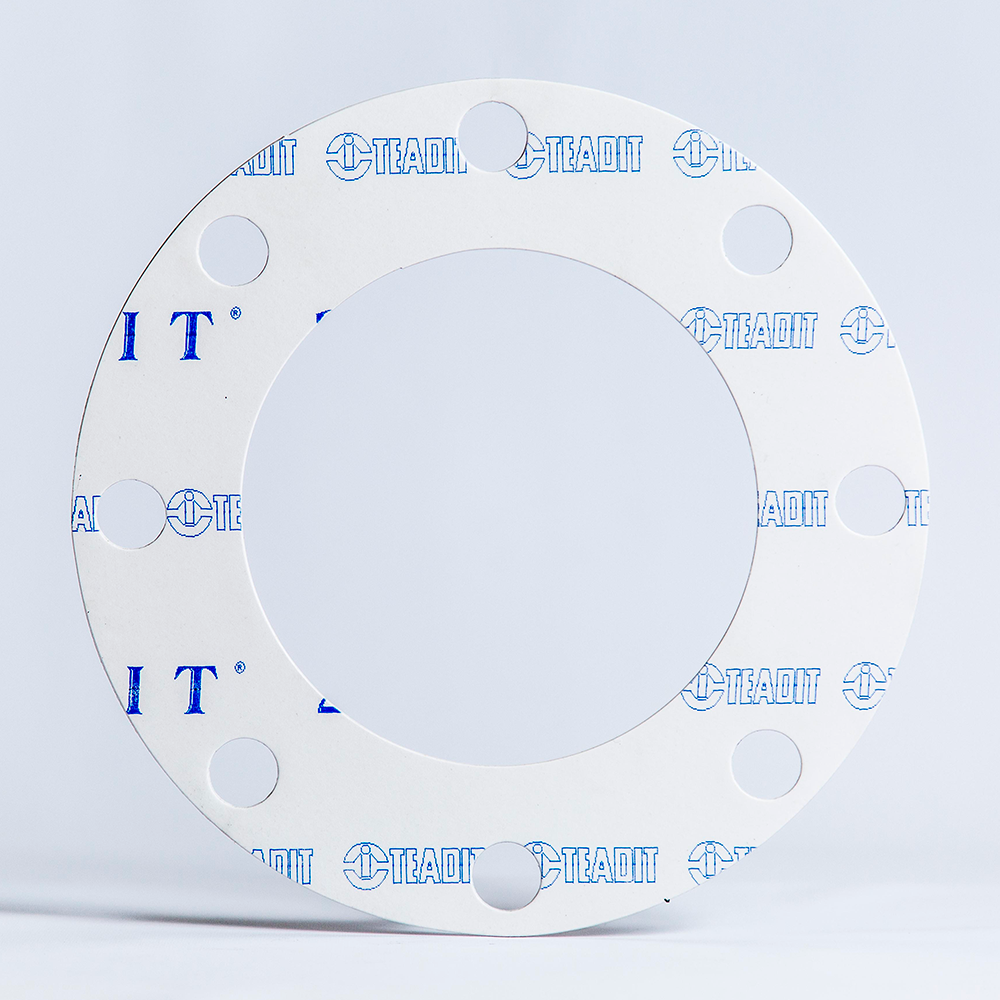

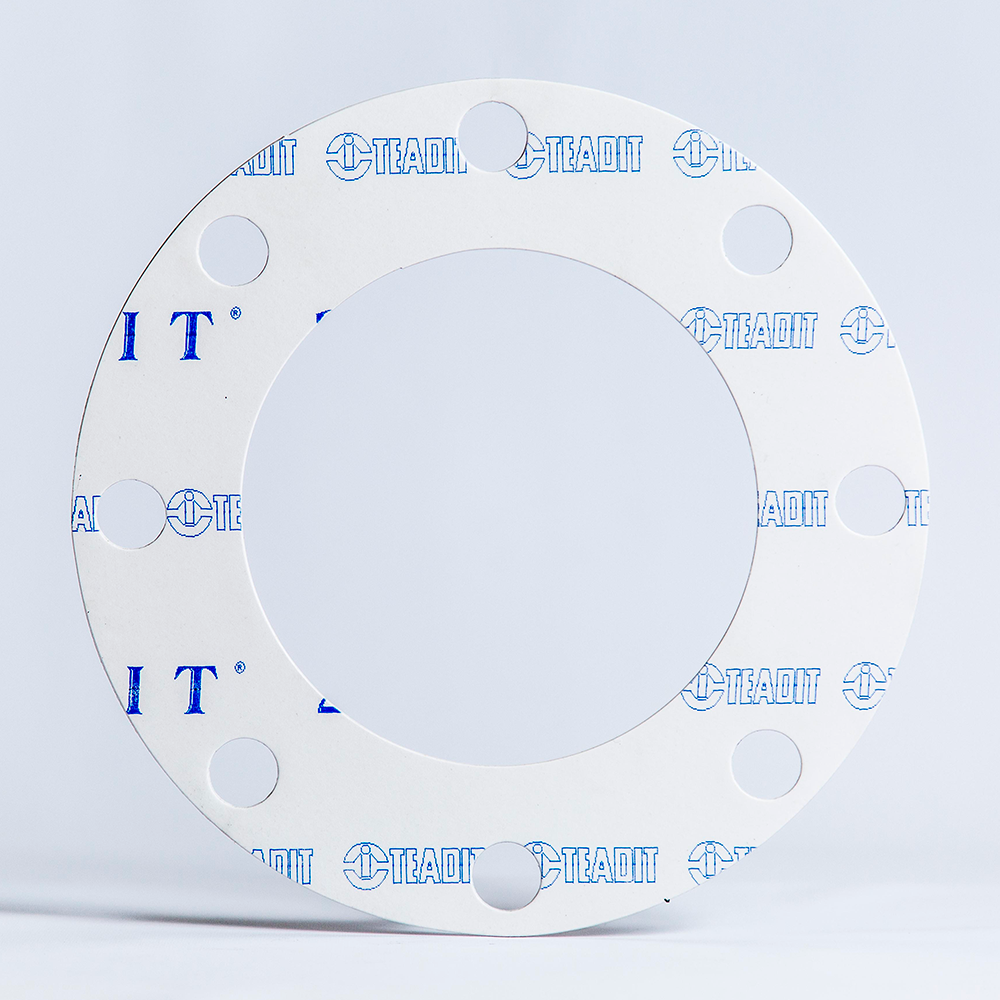

A polymer with exceptional chemical resistance, Polytetrafluoroethylene (PTFE), is the most widely used plastic for industrial sealing. The only media that can chemically attack PTFE are liquid alkaline metals and free fluorine. PTFE has excellent properties for electrical insulation, anti-stick, impact resistance and an extremely low coefficient of friction.

Expanded PTFE is manufactured by expanding 100% virgin PTFE using a proprietary process that produces a uniform and highly fibrillated microstructure with equal tensile strength in all directions. The lightweight ePTFE exhibits characteristics significantly different than any other type of PTFE sheet manufactured. This sheet is much softer, more flexible, and easier to compress than skived or restructured PTFE sheets and thus conforms easily to irregular and rough surfaces. Even though the sheet is soft and easy to compress, when PTFE fibers are expanded in a controlled manner, they become extremely strong. These high strength, biaxially-oriented fibers make ePTFE the PTFE product with the lowest creep and cold flow. Therefore, ePTFE can be safely used in temperatures that might cause other styles of PTFE to creep, lose bolt load, and leak. Expanded PTFE gasketing products are available flat sheets, rectangular profile sheet-like gasket tapes, and form-in-place joint sealant.

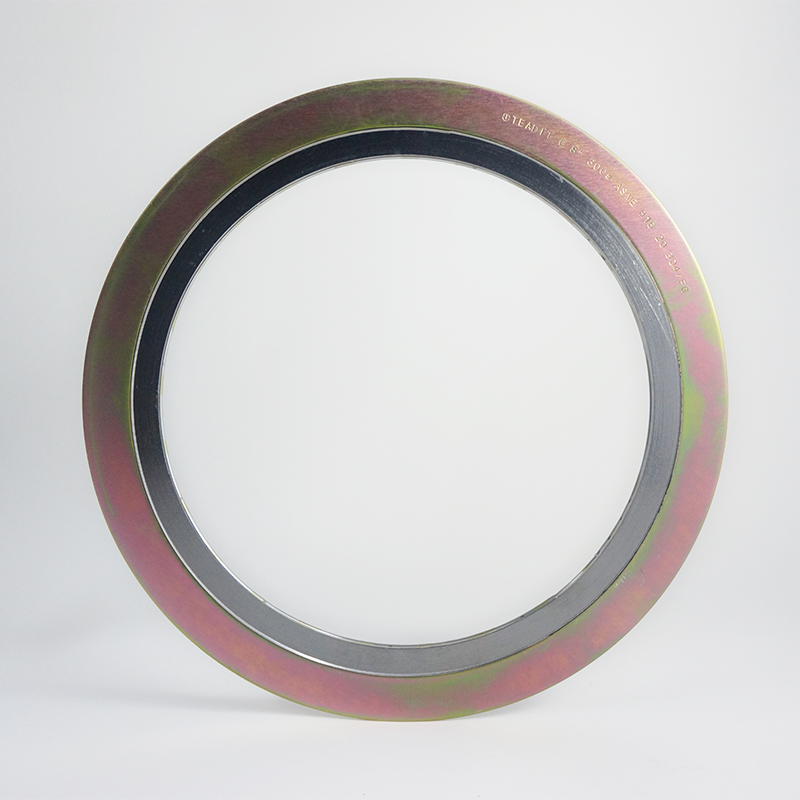

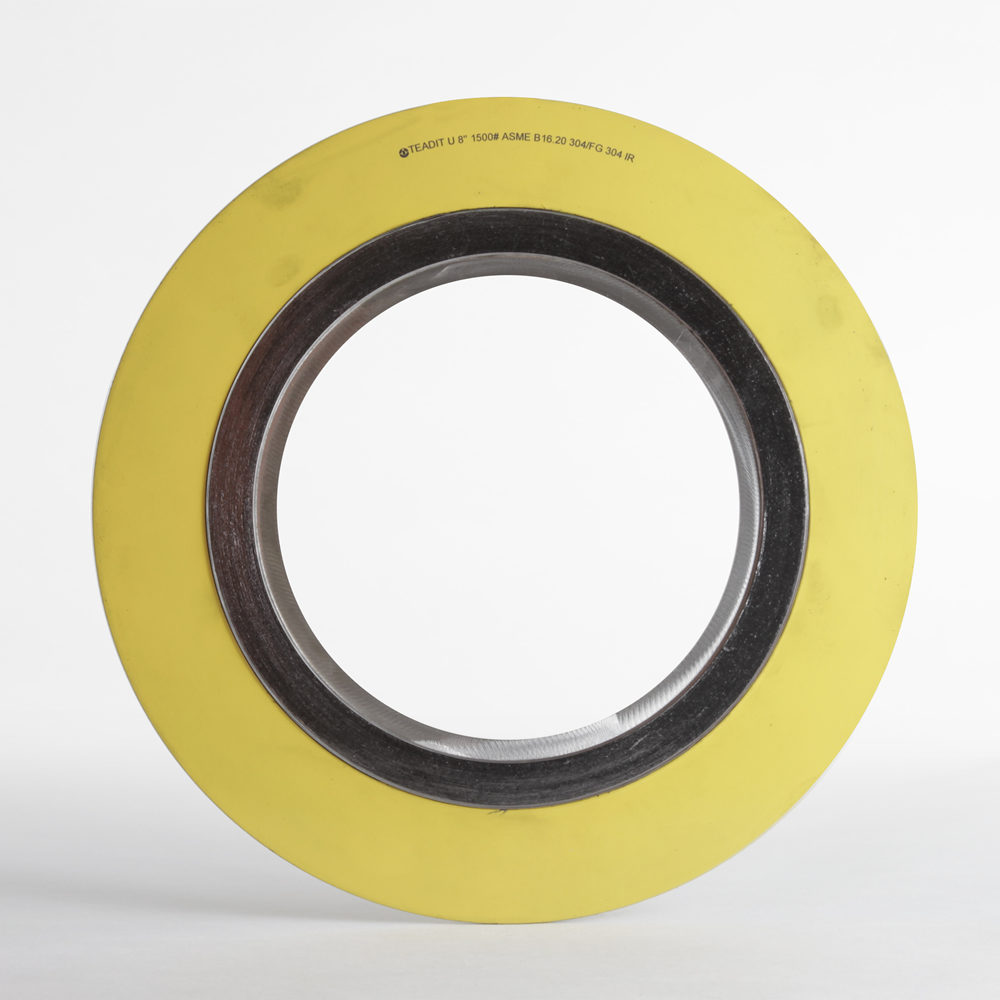

From extreme temperature or pressure applications to aggressive chemical exposure, there is a Metallic Gasket available for every application. We offer a wide range of Gaskets.

Showcased here are just a few of our FDA-compliant products. This designation assures you that each item has undergone thorough testing and met the strict safety and effectiveness standards established by the U.S. Food and Drug Administration. Our products prioritize your well-being. This commitment to FDA compliance reflects our dedication to providing you with confidence and peace of mind when choosing RANAS products.

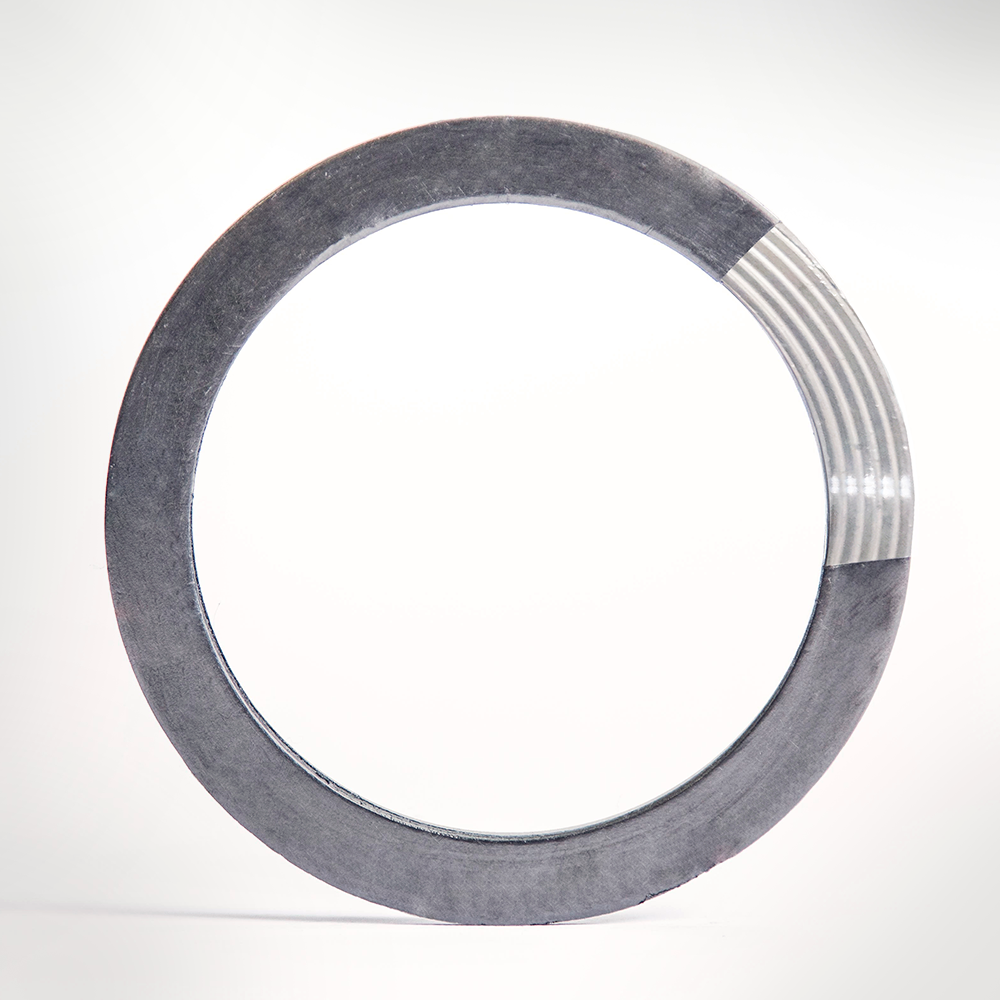

Flexible graphite sheet has pressure-temperature sealability capabilities that are far superior to all compressed fiber reinforced sheet materials. It is resistant to chemical attack by virtually all organic and inorganic fluids with the exception of concentrated, highly oxidizing acids. Gaskets cut from flexible graphite sheet seal with low to moderate bolt loads and because of very low creep relaxation, re-torquing is rarely required. Flexible graphite conforms to irregular flange sealing surfaces and readily flows into flange irregularities enabling it to seal both smooth and coarse surface finishes.

Founded in 1997, a leader in engineering and trading solutions, specializing in wastewater treatment and industrial applications. With over two decades of experience.

Proudly Developed by SKYRISE © 2025