Expansion Joints are designed to accommodate the thermal expansion or contraction of pipes, ducts and other equipment subjected to temperature fluctuations of hot and cold fluids. This thermal growth is one of the main difficulties encountered when designing interconnecting piping or ducting.

• Design and manufacturing according to EJMA and ASME standards

• Wide metallic expansion joint production line

• They can work as vibration isolators

• They compensate small misalignments between pipes or equipment

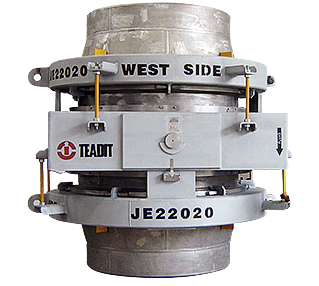

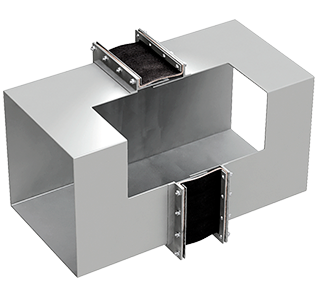

Belt Type

This configuration allows flanged or welded connections. Its geometry is more favorable to the fabric belt manufacture. This configuration has the advantage of easier belt replacement, without the necessity to disassemble the expansion joint metallic frame.

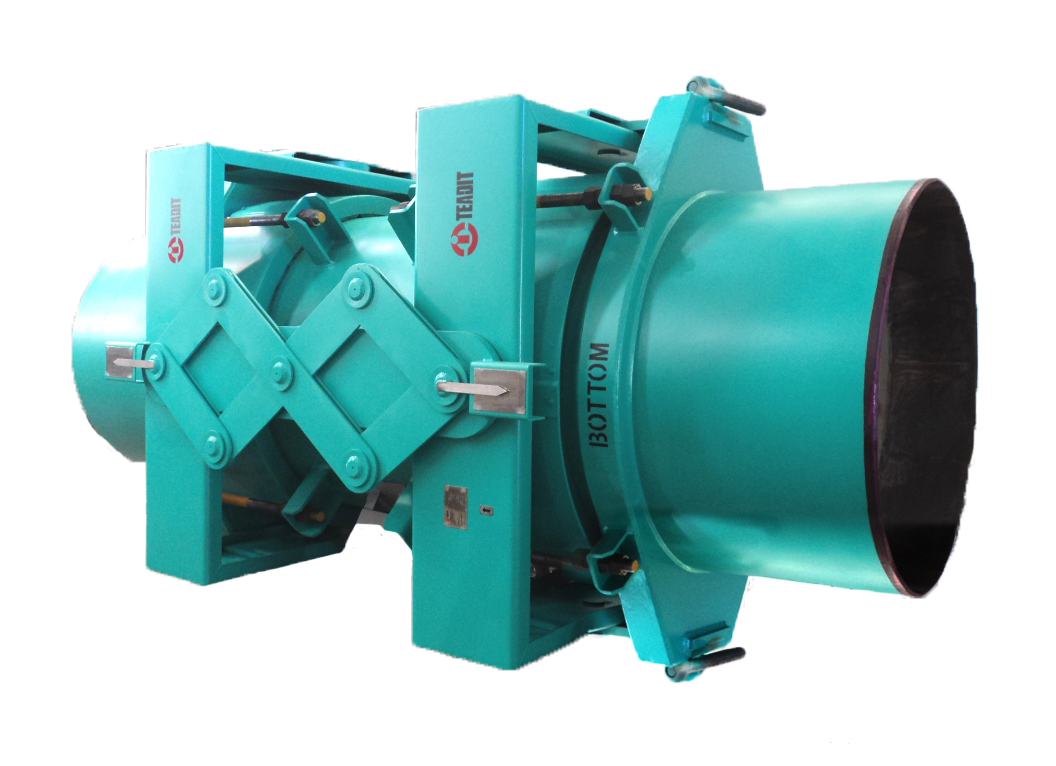

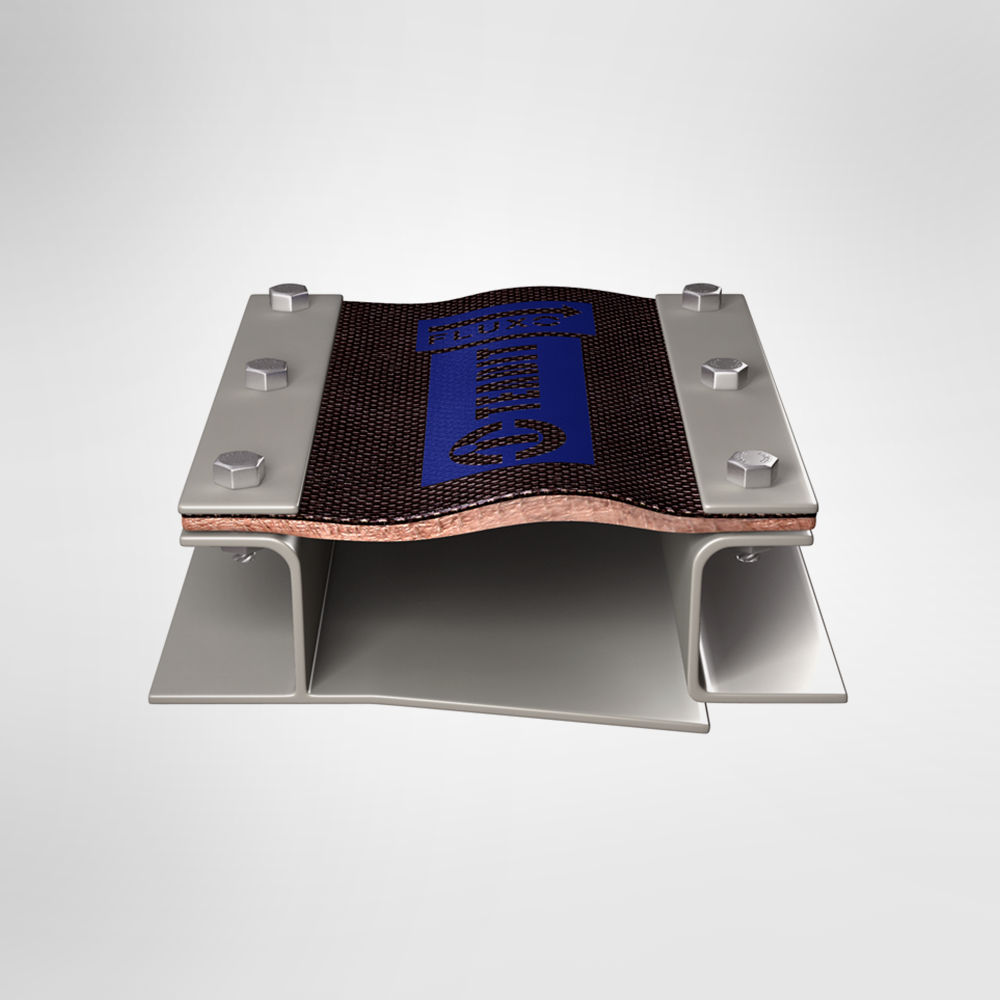

Flanged Type

This configuration has flanged connection and “U” belt profile. It allows small OAL and a simplified metallic structure, reducing the initial expansion joint cost. Nevertheless, it doesn’t allow an easier belt replacement, which increases the maintenance cost.

Founded in 1997, a leader in engineering and trading solutions, specializing in wastewater treatment and industrial applications. With over two decades of experience.

Proudly Developed by SKYRISE © 2025